Project Objective

Supply of a new Coffee-Mate creamer packaging line for the processing of large bottle PET containers.

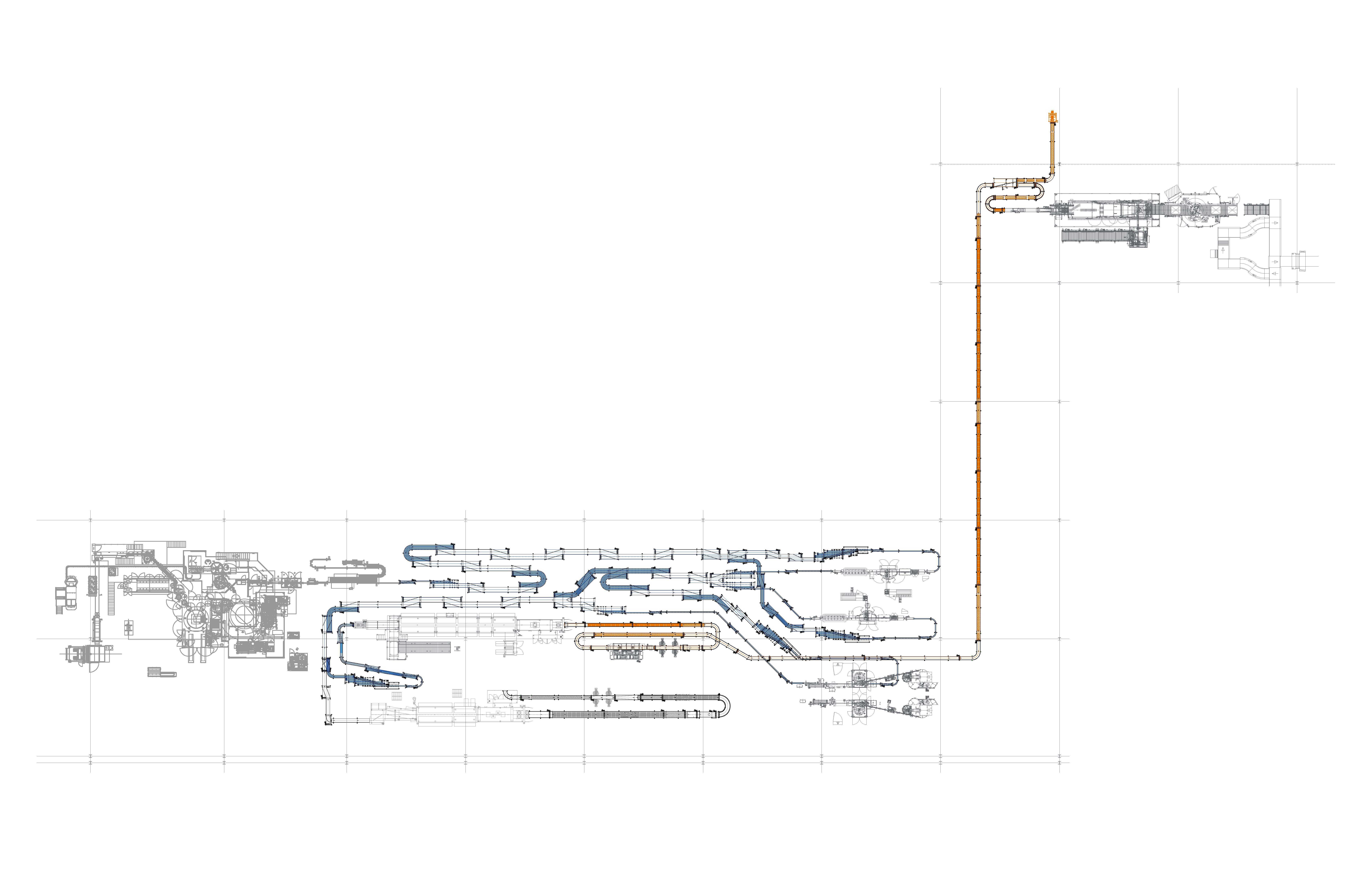

Project Overview

In addition to conveyor systems layout and supply, Descon provided project management services and the complete integration of new PET filling line for Coffee-Mate creamer which included a Krones aseptic filling machine, (2) Fuji Seal sleeve labelers, (2) Arol Euro VP capping machines, a Douglas WSP80 packer, an Intelligrated 942 palletizer, and Lantech stretch wrappers, coding and inspection equipment.

Container Formats

- 56oz PET

- 64oz PET

Primary Package Formats

- 6pk wrap-around box

Secondary Package Formats

- None

Descon Supply and Responsibility

- Project management services

- Plant layout development

- Full PET delivery system

- Mass conveyance, pressureless single-filing and servo laning, auto dry lube system

- Full case delivery system

- Modular belt conveyors with nose-over type transfers, automatic case guides with DC motor drive changeover (no pneumatics), underbody protection and safety netting

- Integrated control system

- NEMA 4X motor control panels

- Danfoss OneGearDrive and FCD Distributed Motor Control

- EtherNet IP networking between all machine centers

- Line simulation study

- “Soft” container handling PLC control code

- Operator machine interfaces (HMIs)

- Platforming and mezzanines

- Integrated electrical wireways and plug-and-play cabling systems

- Turnkey installation services

- Start-up and commissioning services

Products Employed