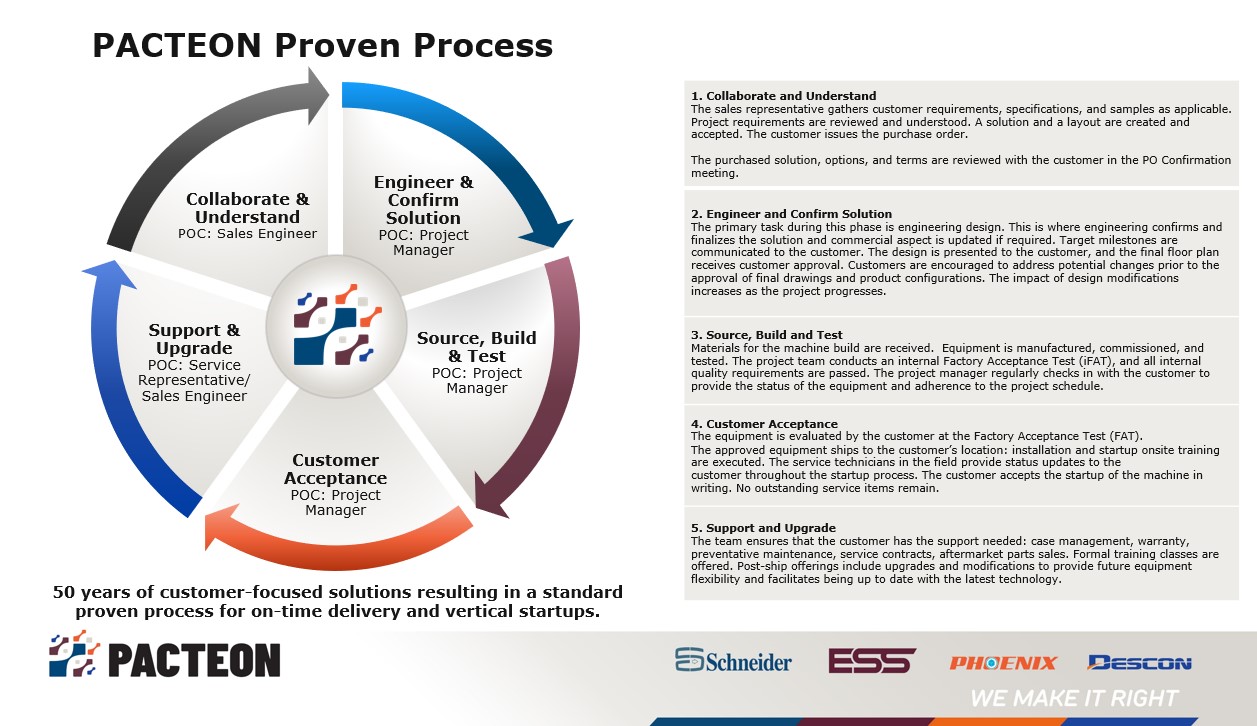

At Descon, we approach each project with a methodical, tried-and-proven process that allows us to properly assess the situation and craft the best solution for your packaging line.

Our process helps make sure that we’ve checked all the boxes and considered each detail, so nothing is overlooked.

From start to finish, we are here to help you get the most out of your production line!

We manage each aspect of the line engineering for your system, including:

Line Audit

The first step to providing a new conveyor system is our line audit to assess current performance and capability. We complete a full evaluation which then becomes our guide when developing your layout designs. Often this stage is a review of drawings and an evaluation of what needs to happen to maximize efficiencies. We identify bottlenecks and constraints, then incorporate solutions into our new design.

Layout Design

This is a vital step in achieving an efficient and balanced production line. Our designs can intelligently integrate into both new and existing packaging solutions. This process takes into consideration factors such as plant floor space restrictions, material flow, operator work areas, forklift traffic, machine accessibility, and evaluation of accumulation buffer zones which increase production throughput. We use a Matterport 3D Scan of the production facility as a tool to collaborate with our customers to discuss continuous improvement measures to achieve the most efficient overall design.

Project Management

Every installation project contains a lot of moving parts. To ensure nothing is lost in the shuffle, we have a dedicated project management team committed to facilitating design, manufacturing, assembly, installation, and final signoff. Through rigorous attention to detail, nothing is missed.

Engineering

We focus on safety, functionality, durability, and maintainability. Our detailed conveyor standards are at the leading edge of 3D-CAD design. We leverage modern technology to engineer new systems quickly and accurately.

In-house Manufacturing and Assembly

We build our products using high-accuracy, laser-cut folded sheet metal and machined components in both stainless steel and painted mild steel. All our products are fully assembled and tested in our shop before shipping. Bringing manufacturing in-house allows us to quickly react to project demands and maintain an exceptional level of quality control.

Installation

Our experienced team of individuals is capable of providing full turnkey installations, starting with generating bid scopes, evaluating contractor installation proposals, managing installation budgets, and overall site management of contractors. For both site management and site supervision we have a diverse team dedicated to delivering high-quality installations on time and on budget!

Commissioning & Ongoing Site Service

Our commitment to develop best-in-class service engineers has resulted in a group of talented individuals that care about our customers’ overall investment. Our goal, “fastest ramp up” and to exceed the customers expectation for overall line efficiency and production throughput. Whether it’s a new start-up or providing service, we act with urgency and are committed to providing an excellent experience for our customers.

Contact us or request a quote to learn more about how we can assess and improve your packaging solution lines.